Updates

Share

Adjustments/updates to the design

01/02/2023 - Part added: Brake

When the drill was switched off, the plate rotated even further, but the middle screw remained stationary. This sometimes allowed the gears to become unscrewed, which caused frustration. When using the brake, the system can now brake suddenly and evenly because all gears are locked. Nothing can now be unscrewed during this action.

02/15/2023 - Part added: Screw blocker

When the system brakes abruptly via the brake, there was a chance that the center screw could loosen due to the shock. The screw shield blocks all horizontal movements and can no longer be unscrewed .

12/10/2023 - Gear teeth size reduced

The teeth of the gears have been reduced in size by 0.1mm to provide more tolerance between the moving parts. The gears now rotate more smoothly.

01/02/2024 - Parts added: Bearing clamp (orange) + extra ball bearing

An extra ball bearing has been added in the middle of the plate to provide more stability to the system. The two additional bearing clamps (orange color) are pressed into the bearing and ensure that the hexagon bolt is supported within the bearing.

29/02/2024 - Diameter of bearing clamp increased

The diameter of the orange bearing clamps has been increased by 0.2mm. This causes it to clamp more tightly on the inner ring of the center ball bearing, which ensures optimal stability

24/03/2024 - Tolerance between internal nut and gear decreased

The size of the opening where the nuts are placed during 3D printing, are decreased (smaller tolerance). The nut is now more tightened into the gear, making less room to move around. The middle gear will now spin more stable.

21/04/2024 - Inner diameter of the bearing clamp (black) increased

We are very aware that the assembly of the bearing clamp onto the hookscrew is quite difficult. To make the assembly easier, we have increased the inner diameter with 0,1mm.

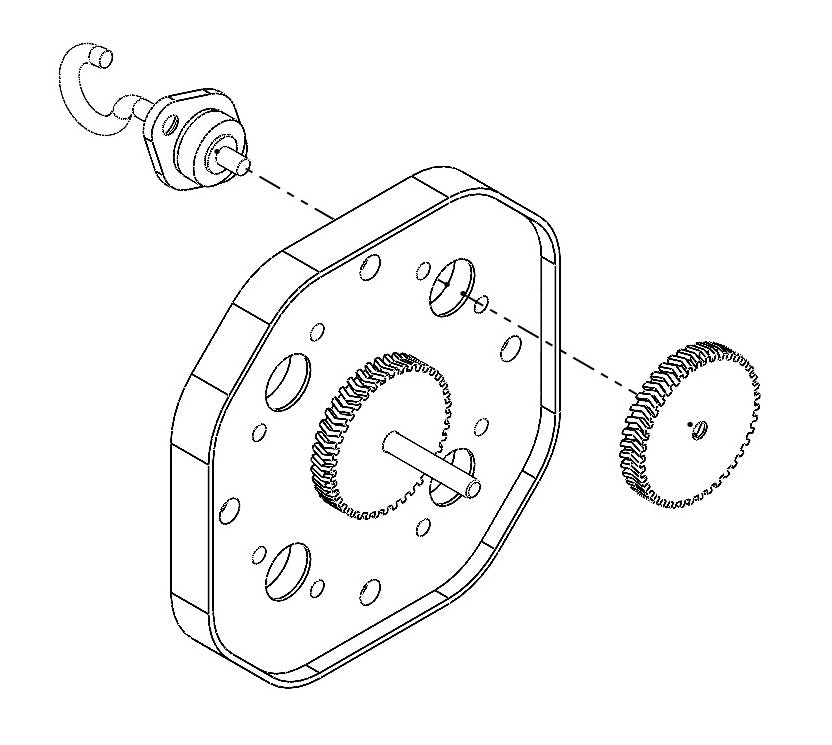

3D printed parts

| Element | Material | Description |

| Gears | PETG | Used to drive the hook screws |

| Center wheel | PETG | Possibility of braking the system + fixing the middle screw |

| Bearing shield | PETG | Keep the bearings positioned correctly |

| Bearing clamp (orange) | PETG | Ensure distance between gear and plate + distance between centering wheel and plate |

| Bearing clamp (black) | PETG | Hold the individual ball bearings in place |

| Cordmaker plate | PETG | Assembly of all parts |

| Plexiglass spacer | PLA | Ensure there is a distance between the gears and the plexiglass |

| Brake | PETG | Possibility to have the system brake quickly and controlled |

|

Screw blocker |

PETG |

Locks the hex bolt in the center of the plate. Without this part, the screw can loosen during braking |